Wet Film Thickness (WFT)

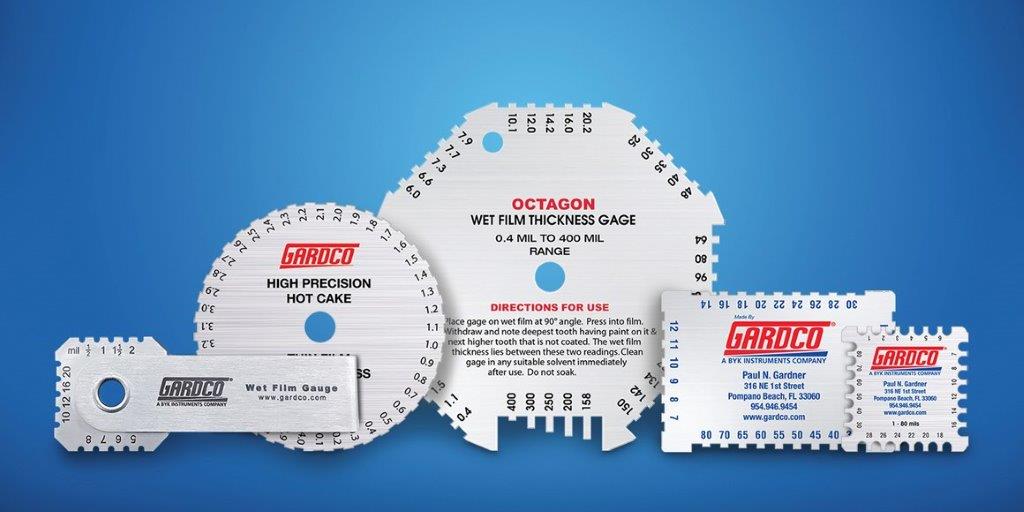

Wet film thickness (WFT) is the measurement of the thickness of an applied paint or coating before it dries. Wet Film thickness is measured using a Wet Film Thickness Gauge. Wet Film Thickness Gauges provide an inexpensive, quick and easy method to measure the thickness of coatings immediately after application. They can be used over a large wet film thickness range, from thick protective coatings to thin coil coatings. Wet film gauges can be used on virtually any substrate.

Wet Film Thickness Gauges are designed to quickly and easily measure paint and coating thickness immediately after application and before curing. They are commonly known as Wet Mil Gauges, WFT Gauges, Combs, Comb Gauges, Mil Gauges, Step Gauges and Notched Gauges. They incorporate a series of notches much like the teeth on a comb. The wet film thickness of uncured applied coatings including paints, roof coatings, powder coatings, intumescent coatings, gel coats, wood coatings, etc. are easily measured with a Wet Film Thickness Gauge.

Wet coating thickness measurement or wet film thickness measurement helps the applicator to ensure that the coating is applied in accordance with the manufacturer’s specifications. Applying too much coating can cause many problems, including excess drying time, solvent entrapment, cracking, sagging, and excess coating material costs. Applying too little thickness can result in the need to apply additional coats, premature coating failure, improper hiding, poor appearance, and a host of other problems that ultimately can lead to additional time requirements to finish the job, as well as claims against the applicator and lost profits.

Wet film thickness should be measured by applicators right after the coating is applied, before significant solvent evaporation occurs to ensure correct measurements. Even slight delays in measuring could result in incorrect low readings, since solvents may have evaporated from the film before the measurements were made. Multiple readings should be made throughout the application process to ensure that the WFT is consistent on all parts of the coated surface. For this reason WFT gages are mostly used by applicators rather than inspectors.

Wet coating thickness should be monitored frequently to maintain and assure a consistent coating process that is in accordance with the manufacturers specifications. It also helps to control the cost of the coating as well as application time, improving overall efficiency and profitability for the applicator. Spray gun speed, number of passes and spray tips can be adjusted to apply the desired amount of coating to meet the specified wet film thickness and ultimately the specified dry film thickness, which can then be measured by a dry film thickness gauge.

It is possible to predict approximate dry film thickness by measuring wet film thickness. Dry film thickness can be calculated by using the ratio of solids to liquids. For example when a coating contains 80% solids and 20% liquid, as the coating dries the liquid evaporate, leaving only the solids in the dry film. So, if the wet film thickness is 100 µm, the dry film thickness will be 80 µm (100 µm x 80% = 80 µm). Dry film thickness, or DFT is the thickness after all of the liquid has evaporated. DFT = WFT x % solids. By simply reversing the equation DFT can also be measured to determine what the applied WFT was.

How to Use

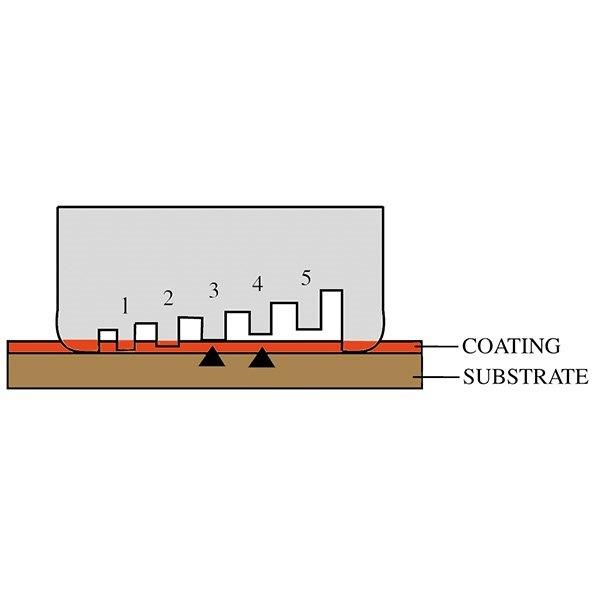

Wet Film Thickness Gauges have notches (also called teeth) cut into the sides of the gauge that are referenced to each other. The two outside notches are the same size and rest on the substrate as a zero reference. The other notches on the same side are shorter and reference the depth of the wet coating as well as the distance from the zero reference. These different distances represent the distance from the surface of the substrate and are graduated in mils (0.001”) or microns. These gauges are very easy to use:

- Place gauge on wet coating at a 90° angle perpendicular to the substrate

- Slowly press into the coating until making contact with the substrate

- Remove the gauge and note the deepest tooth with coating on it and the adjacent tooth that is not coated

- The wet film thickness lies between these two readings

- Clean the gauge in a suitable solvent immediately and dry after use, or properly dispose it

The drawing example on the right shows that the gauge tooth marked 3 mils has just made contact with the wet coating, but the tooth next to it, marked 4 mils, has not touched the coating. This indicates that the wet film thickness measurement of this coating is between 3 and 4 mils thick.

When measuring powder coatings the gauge should be dragged through the uncured powder coating to ensure adhesion of the coating to the gauge teeth. In summary Wet Film Thickness Gauges are:

- Easy to use

- A low cost way for coating manufacturers and applicators to avoid claims due to incorrect coating thickness application

- Inexpensive enough to be disposable

- Customizable for very little cost

- An integral tool in providing a high quality coating application

Comply with the requirements of the following International Standards: ASTM D4414, ISO 2808-7B, BS 3900-C5 Method 7B, NF T30-125, NASI/NCSL Z540-1